Tubular Transport Running System TTRS®

Not all systems are created equal. At Global Gravity, we invented the world’s first Tubular Transport Running System (TTRS), TubeLock® – a system used not just for transport but for handling your pipes right up until they go into the well.

At Global Gravity, we are committed to safety on a global scale. Using our system reduces CO2 emissions, as handling time is significantly reduced, meaning less polluting operational time for both cranes and supply vessels. On backload, our system is packed neatly, taking up less space on the supply vessels, again meaning less polluting trips back and forth.

The oil industry must reduce its CO2 emissions by an incredible amount before 2030, and though using our system won’t fix it all, it is the easiest step in the right direction. Order today and be operational tomorrow.

Improve safety, save money, time, and reduce CO2 emissions

The task was simple for us: Improve pipe handling safety offshore. What we didn’t expect was that safety was just one of the benefits our customers experienced. The feedback we get is astonishing, as customers report significant savings in time, money, and carbon emissions, in addition to improved safety. And all because of a better handling system.

Yes. It sounds too good to be true, but it is quite logical and straightforward. So check out the illustration video for a more in-depth understanding of why the TubeLock® TTRS system is a game-changer.

Safe working - and much more

TubeLock® is the future of pipe handling - but you don't have to wait

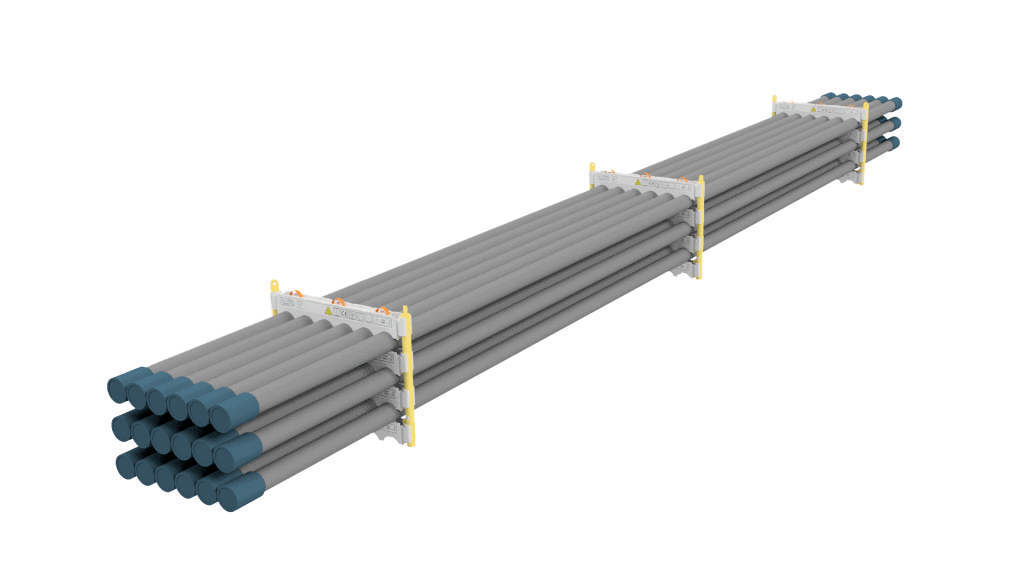

Using TubeLock® TTRS will save you time offshore because pipes can be prepped at the pipe yard by tallying, drifting and fitting with centralisers (if required) prior to load out.

Our case studies show that you will save upwards of 50% of pipe handling time on boat-to-rig handling alone.

TubeLock® TTRS can be stacked much higher than traditional pipe handling methods and will take up less space on the boat.

The main gain, however, is that pipes in TubeLock® TTRS can be lifted directly from the supply vessel to the pipe deck - never having to touch down on the main deck, saving a whole deck worth of space effectively..

On the backload, the frames take almost no space, as they are stacked neatly in containers, saving truckloads of space.

Because TubeLock® TTRS saves you time and space, it also saves you money. You can reduce your rig time, the amount of money spent on fuel for cranes and boats and trucks, and even the number of personnel required in the pipe yard because pipe handling with TubeLock® TTRS only takes a few people.

TubeLock® TTRS significantly reduces CO2 compared to standard slings and 3rd party researched carbon footprint on a full life cycle - from the cradle to the grave.

The study shows a reduction of 35.21 tons of CO2 eq compared to regular slings. The total GHG emission of TubeLock® TTRS is 16.6 tons CO2 eq and of regular slings 51.58 tons CO2 eq. You can reduce your CO2 emission by just choosing the safer and more sustainable solution.

The difference in saving corresponds to 7,2 trips around the world.

Use TubeLock® TTRS for any type of pipes

Reduce your CO2 emissions automatically

Reducing your carbon footprint is no easy task – especially not for a drilling operation. That is why it makes perfect sense to make the simple adjustment of just switching your pipe transport method in order to automatically reduce your emissions with countless crane, boat and rig hours while simultaneously improving efficiency and reducing waste.

We know that time is money, and one of the biggest worries big companies have when switching out the old ways is that new systems are hard to learn and costly to install – both because of errors in first use and retraining the crews.

You won’t find that problem with TubeLock® TTRS. Our system is ready to go and easy to use. We have extensive training videos showing you and your people how to operate the system effortlessly, and you are guaranteed to save time, even at first use. We know this because that’s the feedback we have received from our clients.